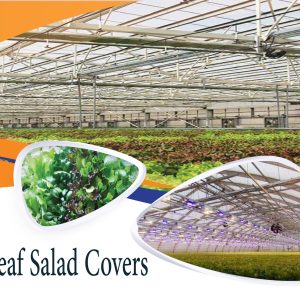

Greenhouses & Low Tunnels Covers

Free

Greenhouses & Low Tunnels Covers After twenty-year experience in the production of agricultural plastic films and the associated cutting-edge technology investments,

Al-Quds supplies a large variety list of PE agricultural plastic products.

Our 5-layer co-extrusion machines enabled us to produce unrivalled quality greenhouse films with uncompromised quality that can withstand extreme conditions.

Greenhouses & Low Tunnels Covers This new line produces films with widths ranging from 0.5 m to 16 m and varied thicknesses from 30 mics. to 250 mics.

- Description

- Cover Film Types & Features

- Folding Types

- Standard Covers

- Green Houses Case Studies

- Reviews (0)

Description

Cover Film Types & Features

You should be aware that the optical properties of each plastic cover are determined according to the needs of your crop and the location of cultivation. Hereinafter some of the technical information about these properties is as follows:

UV STABILISATION

We have had a slightly different philosophy than the others since the beginning of our company, according to the product differentiation strategy. We believe that every crop deserves to be protected for as long as possible. That is why, using our multi-material formula developed over two decades, designed to last at least for the duration of the film’s warranty at your latitude. This one-of-a-kind stabilizer protects our products from UV light and high temperatures. We never put your crop at risk.

RESISTANT TO AGROCHEMICALS

UV stabilising systems can be interacted with and deactivated by agrochemicals. As a result, we can design and manufacture a greenhouse cover or tunnel cover to be highly resistant to chemicals containing Sulphur, chlorine, iron, and other commonly used agrochemicals. All you need to do to get this option is ask our sales team to add it to your product when you place your order.

DIFFUSION

We have developed unique models that predict how much diffusion you will need based on cutting-edge science and extensive commercial trials, and we then manufacture your cover film accordingly. Unlike some other diffusing films on the market today, we guarantee all of our diffusing properties for the lifetime of the cover films if the warranty validity instructions are strictly followed.

THERMICITY

Based on the crop and location, we tailor the amount of thermicity to your exact needs. We do this by combining our unique climate models, 5 layers extruding technology, and advanced thermic additives to smooth out day and night temperature changes, allowing us to better protect your crop while reducing crop stress and heating costs.

ANTI-DRIP

All of our products can have anti-drip properties built in to help reduce the risk of crop fungal diseases. Water will condense uniformly across the film’s surface rather than as droplets if the film is properly installed, reducing both light loss and the risk of water falling on the crop below.

ANTI-DUST

We can add a dust-reducing additive to our cover films. The upper layer of the cover film is especially smooth in this case, which reduces dust accumulation significantly.

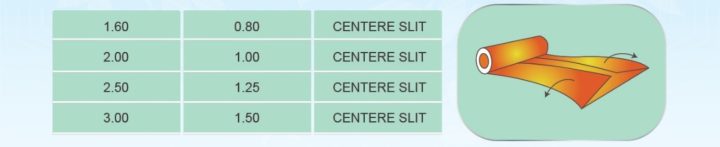

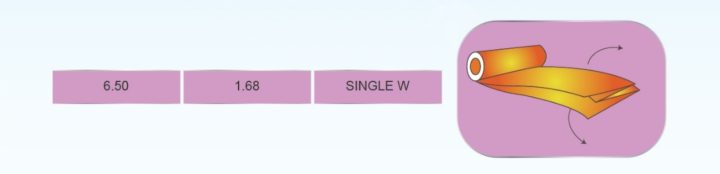

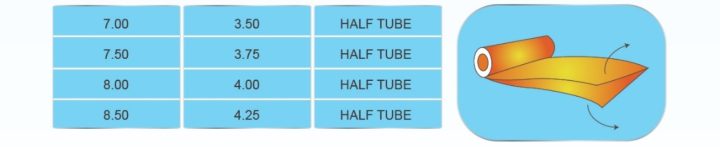

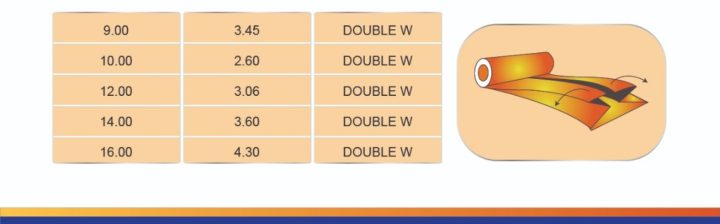

Folding Types

Our cover film folding mechanism is designed to make transporting and storing rolls easier.

Our machine can perform various types of folding such as { Double C, Double W, Multiple W } to reduce the width of the roll to accommodate the cutting process and for easier cladding.

Folduing Type:-

-

C Folding

-

Folding Single W

-

Folding Half Tube

-

Folding Double W

Standard Covers

These covers are commonly used in greenhouse production and they can be designed with a wide range of additional properties to meet the specific needs of farmers.

As you can see, there is nothing standard about it.

As a result, it is based on a formulation that we have spent several years developing with researchers, developers (R&D), and grower partners worldwide.

It was built from the ground up to be the ultimate generalist, delivering enviable yields and quality across a wide range of globally protected crops.

So, once you’ve decided it’s the right cover for you, we get to work on designing all of the other features that make the cover unique to your location and growing system.

We’ll assist you in determining whether you require a clear or diffusing cover.

If you choose the latter, we’ll make it with just the right amount of diffusion for the specific location where you’re growing your crop.

We can also engineer these covers to be SUPER THERMIC, which means there is no better cover to protect your crop from early-season frost and smooth out temperature differences between day & night, and reduce crop stress.

Finally, when you combine our expertise with previously unheard-of manufacturing flexibility,

there is no one better positioned to assist you in making the best decision for your crop.

Green Houses Case Studies

Our recommendations for any crop cover are based on R&D trials of various species at the field station.

Nothing beats seeing with our own eyes. That’s why, we spend every minute we can with our customers, talking to them face to face on their farms, understanding their needs for growing their businesses, and then working side by side with them to deliver unparalleled success.

Most importantly, we work with growers of all sizes, from those growing amazing produce in single-span tunnels to the very largest multi-hectare projects delivering year-round produce into global, fresh produce export markets.

We do this because we believe that knowledge and wisdom can be found at all scales, and while nothing makes us happier than sharing our knowledge with our customers, we also recognize that there is always something new to learn.

Hereinafter, some of the success Green Houses Case Studies we’ve enjoyed with our partners as follows:

Reviews

There are no reviews yet.